THE CLAY

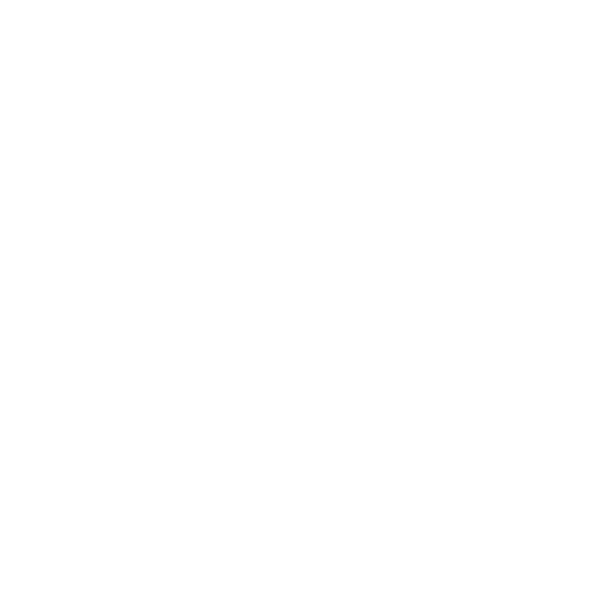

All stoneware pieces produced in the Fusion de Lave Studio are handmade and original creations. Philippe uses all the traditional techniques to work clay, including slab work, throwing, modelling and clay printing to produce one of a kind ceramics.

Once shaped, the stoneware undergoes a slow drying process to allow the clay to gently shrink and let water evaporate. Pieces are then bisque fired (at 980°C/1796°F) to prepare them for receiving a coating of glaze.

LAVA GLAZES

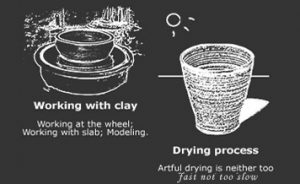

Glazes are made of refractory and smelting components which, if skilfully and artfully measured, will transform into a bright and smooth coating thanks to a firing process conducted at very high temperatures.

In his studio, Philippe uses lava as a basic component for his glazes. He loves combining lava with other components such as various kinds of vegetal ashes – a direct inspiration from traditional eastern traditions – or with other mixed material born out of his own research. Each piece of bisqued stoneware is then dipped in or sprayed with glaze and fired at 1300°C/2372°F. Such a high temperature allows for colours to develop in an unpredictable manner thus crafting the uniqueness of each piece of stoneware.

Results can only be seen after the firing and depend on several parameters (such as the density or thickness of the piece, the atmospheric condition within the kiln, the firing process and the atmospheric condition outside the kiln). All these parameters are voluntarily left as uncontrolled as possible so the soul of the object can emerge from the subtle mixture of skill and pure chance.

In order to explore the mysterious and wonderful world of lava rocks in fusion, Philippe had to conduct hundreds of tests. Today, as a ceramist artist truly in love with his material he is still involved in testing rocks in fusion.